Everything about slicing and vacuum packaging

Since 2000, the slicing of food has not stopped growing. Currently the consumer is increasingly demanding with the presentation and convenience of consumption of packaged foods. This determines that manufacturers and processors must serve the product well sliced and perfectly packaged.

From meats, sausages, cheeses, smoked, processed, sweet ... Zermat offers solutions to adapt to each type of food.

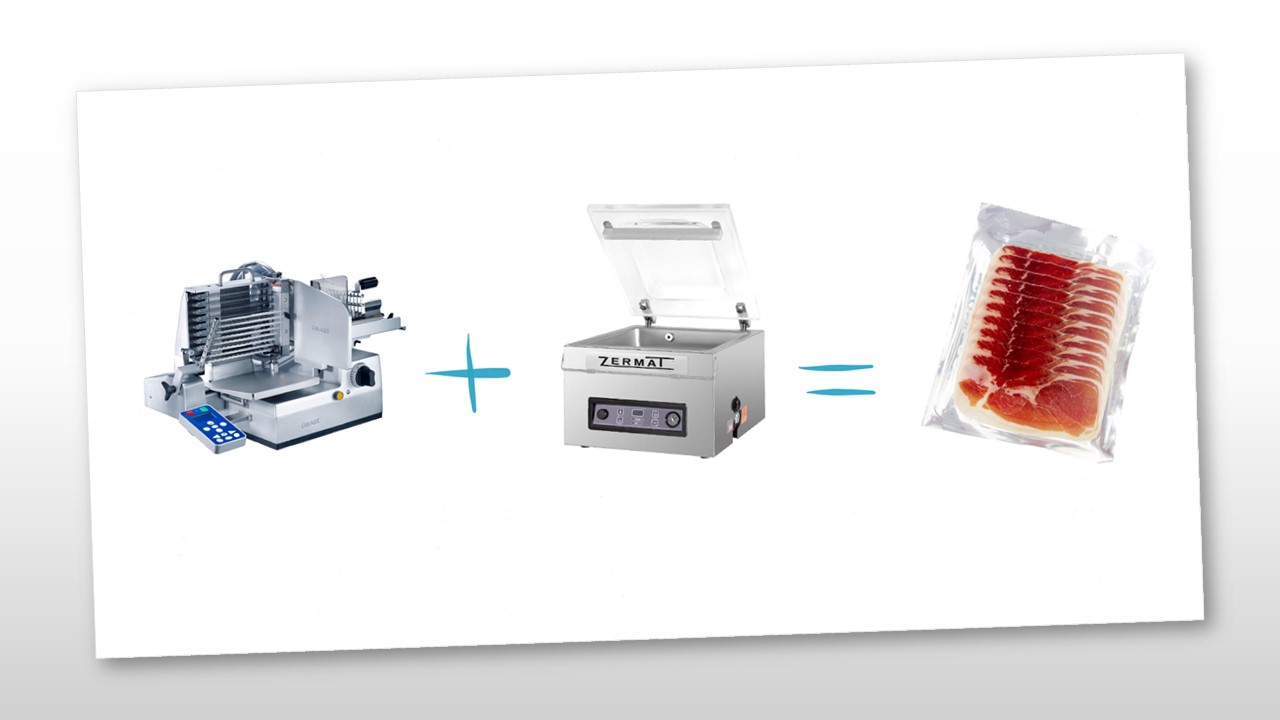

The most innovative slicing and packaging station of the moment: Slicepack

For an impeccable presentation it is essential to have the tools that give us the professionalism that our client expects. There are several steps in the vacuum slicing and packaging process, and now with the Slicepack by Zermat slicing and packaging station, this process can be 100% automated.

The Slicepack slicing and packaging station consists of two well-established products from the Zermat and Graf range: the VA804 slicer and the TB2 traysealer. The two models are the best sellers and preferred by many of our customers.

Always offering solutions

Standardized solutions and automations developed

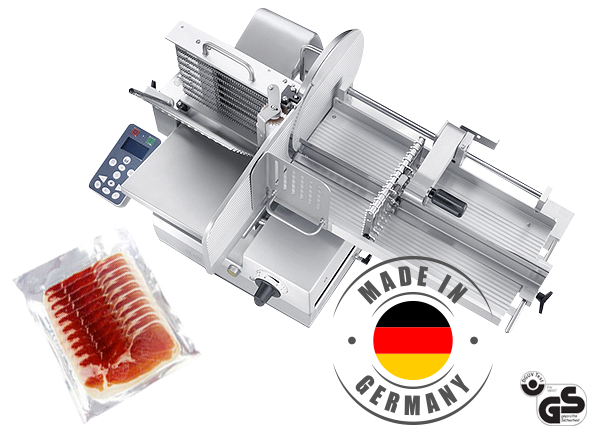

Zermat is an exclusive importer for the Spanish speaking markets of Graef

GRAEF, since 1921 manufacturing high quality automatic slicing for the most demanding specialists.

Wide range of models designed and developed for a maximum precision cut in every food.

Even with the most difficult products, the Graef machine becomes the best tool, always offering maximum safety and ergonomics for the user.

Performance, efficiency and durability, the key factors.

Solutions and standard developed automations

INVAC: slicing with or without separating paper, weight control, bagging and vacuum packaging

TRAYGIVER: system for the slicing of products and positioning on the trays

DISKGIVER: dispenser of paraffined paper dividing sheets or plates support plates for square or circular slices

INTERGIVER: Automatic dispenser of support or dividing sheets between the slices

Do you need more information about slicing and packaging?

Sliced foods vacuum packed in a bag or on a tray?

Each package has its advantages and disadvantages, and according to each food and format, it will be more appropriate to use one type of packaging or another. We must choose intelligently. Read our recommendations.

Bagged packaging:

All advantages:

- Low cost in the container / consumable, only the bag is required

- Less storage space and reduction in transportation costs

- High brightness of the slices and attractive presentation for the consumer

- Products such as Iberian ham, bagged and high vacuum packaging, improves its organoleptic properties

- A Vacuum packer offers the possibility of providing gas injection inside the bag if you have the installation for GAS (optional)

As disadvantages:

-Handling; It costs more to introduce slices in the bag than to deposit them on a tray

- Crushing of the slices and greater difficulty of handling for the consumer

Our conclusion :

The type of bagged packaging is recommended for most whole, sliced or sliced products. Ham, cured meats and sausages, cheeses or fish among others. Any food for sale, commercialization or export.

Video of the bagged packaging

Packaging on tray:

All advantages:

- The attractive presence of food

- Comfort in handling

- Easy to consumption for the final customer. They can open the tray and serve directly to the plate or on the table

-In some cases gas is added to the container, and this can improve the presence of certain foods (eg red meat) reducing the loss of color in the product that the effect of the vacuum produces

As disadvantages:

-In this presentation intervene the costs of the tray, the upper film and the gas to be injected

-Environmental negative effects, the packaging in heat sealing generates more waste

Our conclusion :

This type of packaging is recommended for large quantities or sliced formats with high added value. Currently, due to the high demand for this format of food packaging in the market, the costs to pack in this format are very competitive