Why and for what to use the gas injection?

Once the vacuum process is complete, the bag is ready for sealing. Gas can be injected before this. This technique is called MAP (Modified Atmosphere Packaging). This process is mainly carried out to increase the useful life of the product, provide greater protection and / or prevent the product from losing color. Normally is used a mixture of nitrogen (N2) and carbon dioxide (CO2). Oxygen (O2) can also be added to this combination. Lately, the use of argon (Ar) gas has increased, since it contains the same properties as nitrogen (N2).

Application

Some examples of products where gas injection is useful are: cut lettuce, salad leaves, minced meat, steaks, cooked fish, pre-cooked products, potatoes and ready-to-use products. The proper gas mixture depends on the product. Your gas distributor can offer you better information regarding the optimal composition. A special pump for oxygen (O2) is available for gas mixtures of more than 20% oxygen (O2).

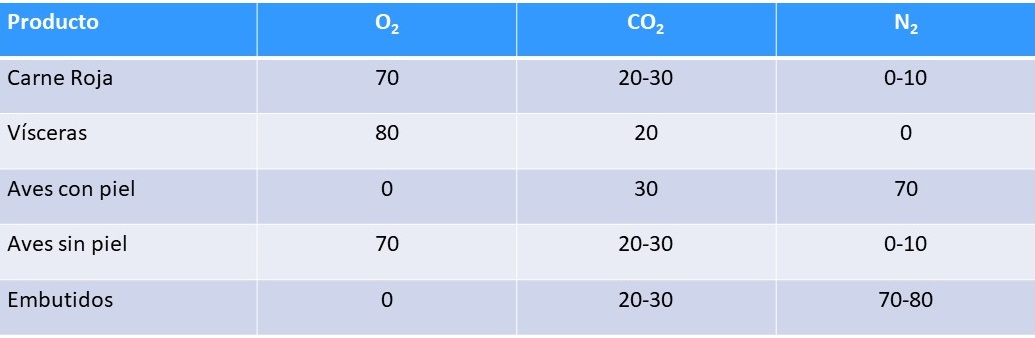

Specification by type of product

Meat products and sausages

Raw meat due to its high moisture content and high nutrient content is very sensitive to decomposition due to the development of bacteria. The most important gas as a protective gas is CO2. This can reduce considerably the growth of these micro organisms. Red meat is in danger of losing its color due to oxidation and turning gray with a slightly unpleasant appearance. This can be solved by adding a high oxygen content in containers with a protective atmosphere. Another option would be to add a small dose of carbon monoxide.

Fish and Seafood

Fish and seafood are especially delicate products. Since they are captured, the danger of decomposition begins, affecting their quality. The most important thing for conservation is to refrigerate it near 0º. CO2 atmospheres can slow down this bacterial growth. Check depends on the type of fish you work with which would be the best combination to ensure optimal conservation

Cheese and Dairy

Cheese decomposes rapidly due to microbiological growth. It is an abnormal protein breakdown, which damages the cheese's crust and generates an unpleasant odor. The main gas that is used in packaging in modified atmosphere to prolong the freshness of hard cheese is carbon dioxide, while for soft cheeses, the proportion is usually 20 to 40 percent. Modified atmosphere packaging is particularly good for gratin or sliced cheeses, since it allows to preserve a space around the cheese when it is packaged. Always consult about your type of product which is the appropriate proportion to achieve the desired results.

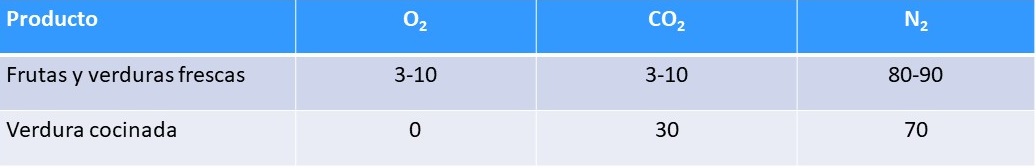

Fruits and Vegetables

Thanks to the modified atmospheres in fresh products, the products can be offered without losing their properties. The effect will be like that of newly caught. The film that surrounds them can not be completely hermetic.

Effects of different gases

Operation

Advantages of Gas Injection

Do you need more information about available gases?

Modified Atmosphere Packaging (MAP)

Oxygen (O2)

as it is the main cause of decomposition in food due to oxidation and favoring the creation of micro organisms, is frequently excluded from packaging.

Carbon dioxide (CO2)

is a colorless gas. Suitable to avoid oxidation and the appearance of bacteria and mold, that is why it is used to prolong the useful life of the product. It is suitable for a type of food since in high doses it can alter the taste

Nitrogen (N2)

is an inert gas. It is used to displace the air, especially the oxygen inside the containers. We avoid the oxidation and growth of bacteria. It can also be used as a filler gas since it evaporates very slowly.

Carbon monoxide (CO)

is a colorless gas. It is similar to oxygen and is very suitable for the preservation of the red color of meat. It is used in small doses. Some countries of the EU are prohibited from using it for food protective atmospheres

More articles

Read more about traysealers with gas injection, discover the applications and the availables machines.