Industrial vacuum packaging machine.

Automatic equipment with programming of continuous cycle or the "hands free" activation by a foot sensor.

Inner belt for automatic bag discharge. The seal bars located at the top.

Vacuum pump. Busch 160m3/h (optional 300 m3/h).

Technical specifications

- External dimensions: 1180 x 870 x 1310 mm

- Chamber inner dimensions: 1054 x 630 x 220 mm

- Seal bars:

- a) 2 x 1000 mm

- b) 1 x 900 mm + 1 x 550 mm

- c) 2 x 900 mm + 1 x 550 mm (3 seal bar optional)

- Vacuum pump: Busch 160 m3/h (300 m3/h)

- Electric connection 3F - 380V - (1F - 230V)

- Power: 5’5 Kw

- Pneumatic connection: 6Bar

- Weight: 490 Kg

Dimensions Characteristics (W x H x H)

Characteristics

- 100% in stainless steel construction.

- Automated opening and closing of the lid.

- Automatic lid closure: programmable or operated with hands-free system (foot sensor).

- Double grooved seal bars with programmable cut-off-seal.

- LED control panel with synchronizable printer.

- Equipment synchronizable with an automatic Shrink tank.

Options

- Inert gas injection.

- 3 seal bar optional

- Cut-off-seal.

- 1-2-Cut-off-seal.

- Internal conveyor belt for the product expulsion.

- Synchronized side belt for product entry.

- Extra height of chamber.

- Installation for external vacuum pump.

- 160m3 / h Busch vacuum pump (outside).

- Automatic top lid in continuous mode or operable by the "hands-free" system with detector sensor.

- Automated bag unloading.

- Shrink tank synchronizable with most packaging lines, reception from adjustable packaging machine and expulsion to an automatic dryer.

- Equipment designed for integration into automatic packaging lines.

- Minimal maintenance.

- Manufactured with working operation for loading-unloading products from right to left (standard) or in the opposite direction, for the best adaptation to each production line.

- Air knife drying system at room temperature and connected to a high power turbine.

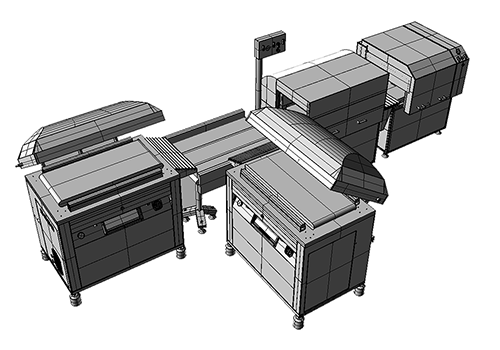

Automatic lines with CV1000 PRO

Twin option, one user controls two computers

Double bell system with the following advantages:

- Each equipment is independent and does not depend on the other (greater reliability in daily production).

- Both units are loaded with product by a single operator.

- The operator must not move for bag loading.

- Belt inside each chamber for the automatic bag discharge.

- Both equipment always unload the bags at the same point, this can be a conveyor belt or a fixed table.

- Synchronizable setting with an automatic shrinking and drying line.

- Possibility of making the investment in two phases.

- Fast and versatile equipment, suitable for high production packaging of all types of products, from cheeses and cured meats, to fresh meats, fish or other components.